Description

TPM is defined as a program that:

- Aims to create a culture and environment that constantly tries to maximize the effectiveness of the entire production system ( in other words, to increase its OEE );

- Uses a hands-on approach to build a ‘zero accident, zero defect, zero breakdowns’ system designed to pre-empt losses of all types throughout the life cycle of the production system;

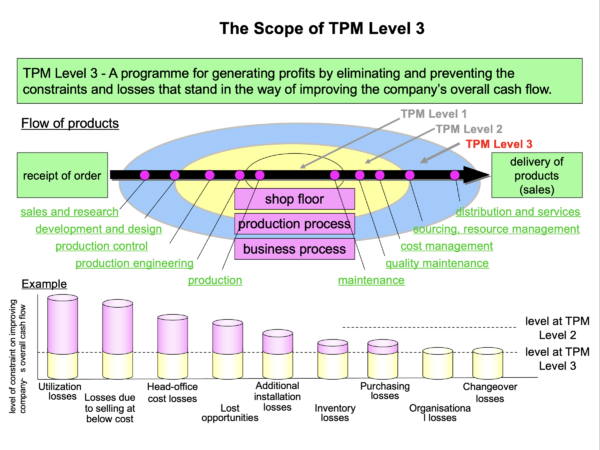

- Includes development, sales, administrative and other departments as well as production;

- Involves everyone at every level of the organization, from top management to front-line employees;

- Uses overlapping small-group activities to attain the target of zero losses.

- 001 – TPM – An Overview

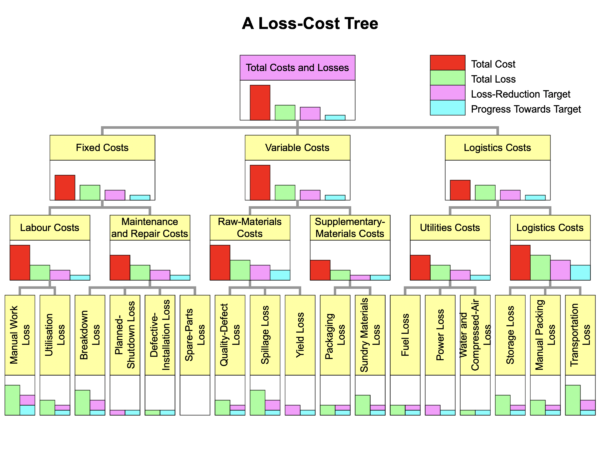

- 002 – Losses, Costs, and Efficiency

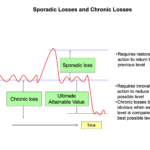

- 003 – Chronic and Sporadic Losses

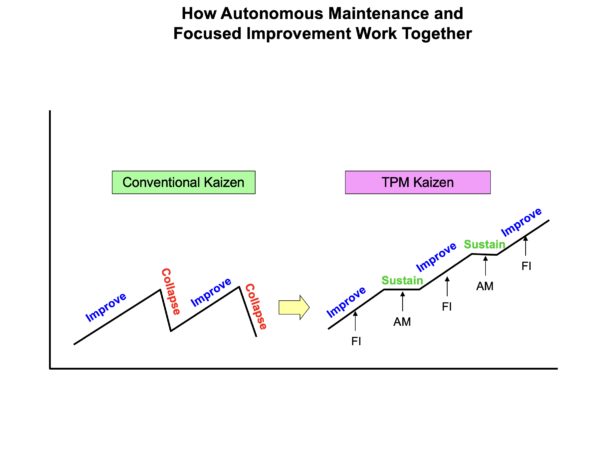

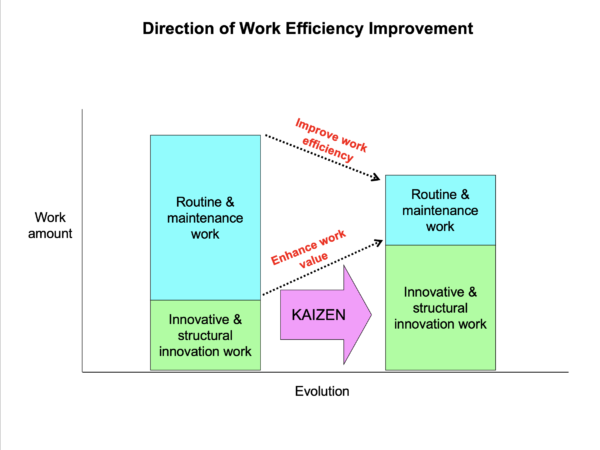

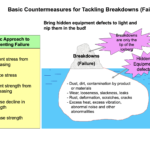

- 004 – Focused Improvement

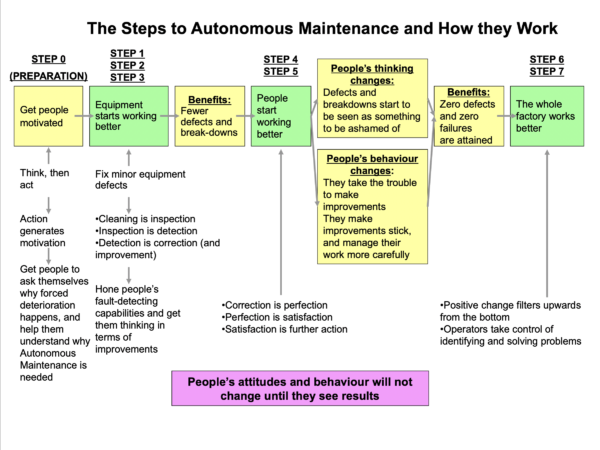

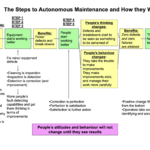

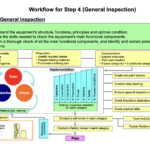

- 005 – Autonomous Maintenance Step 1 to Step 3

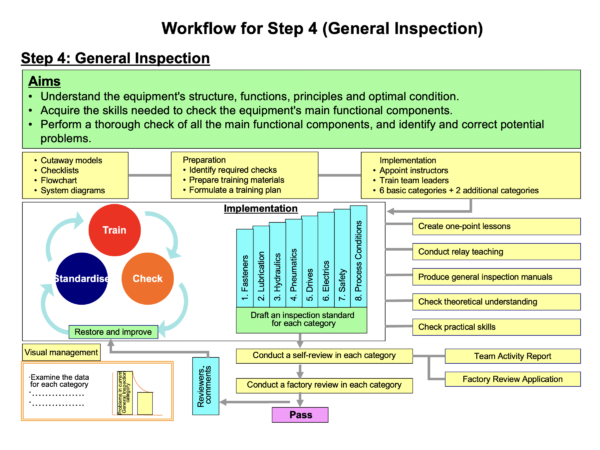

- 006 – Autonomous Maintenance Step 4 to Step 7

- 007 – Effective Maintenance

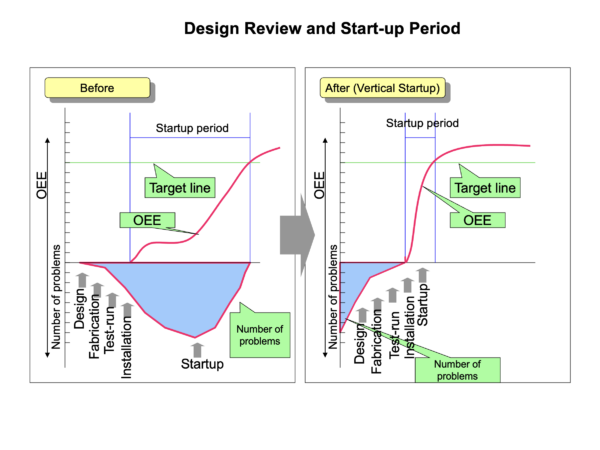

- 008 – Early Management

- 009 – Quality Maintenance

- 010 – TPM in Administrative and Support Departments

- 011 – Completing and Upgrading the TPM Programme

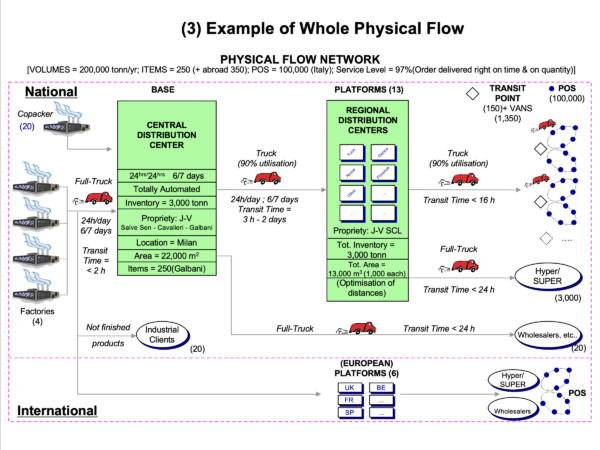

- 012 – TPM – SCM

Reviews

There are no reviews yet.