Description

Description:

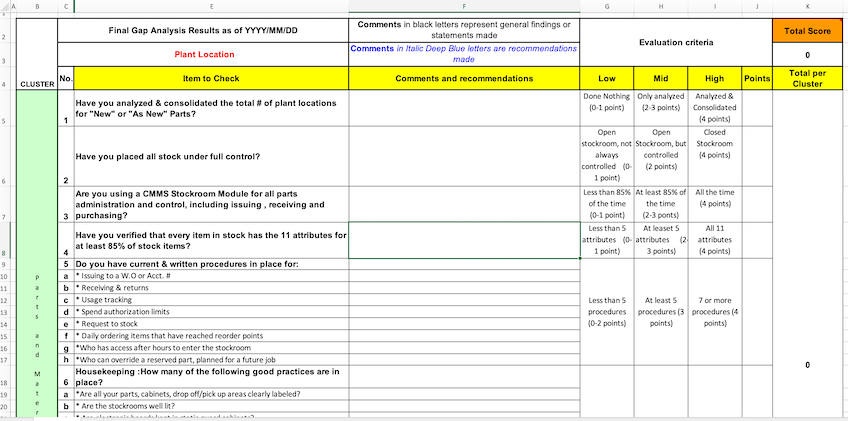

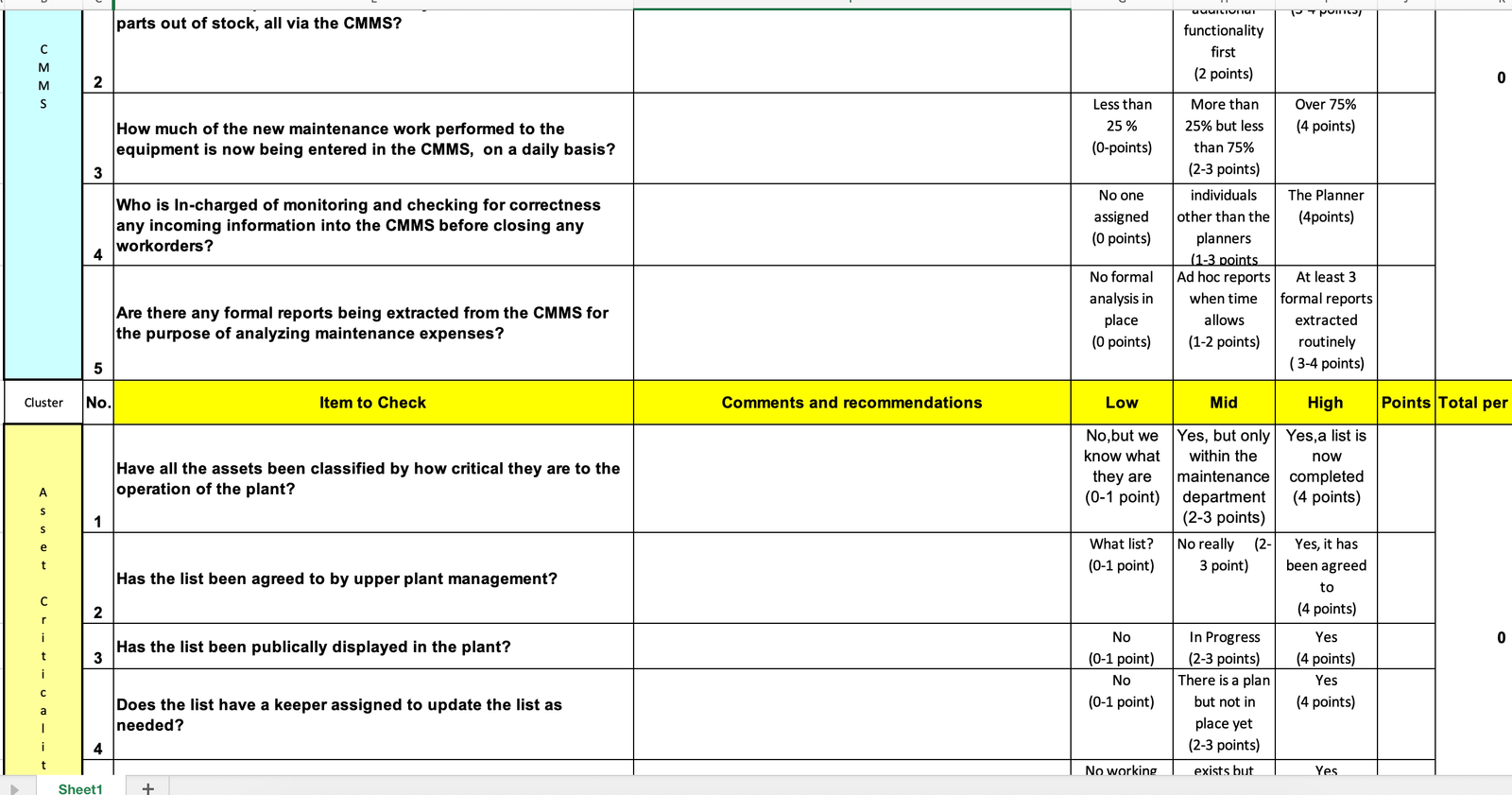

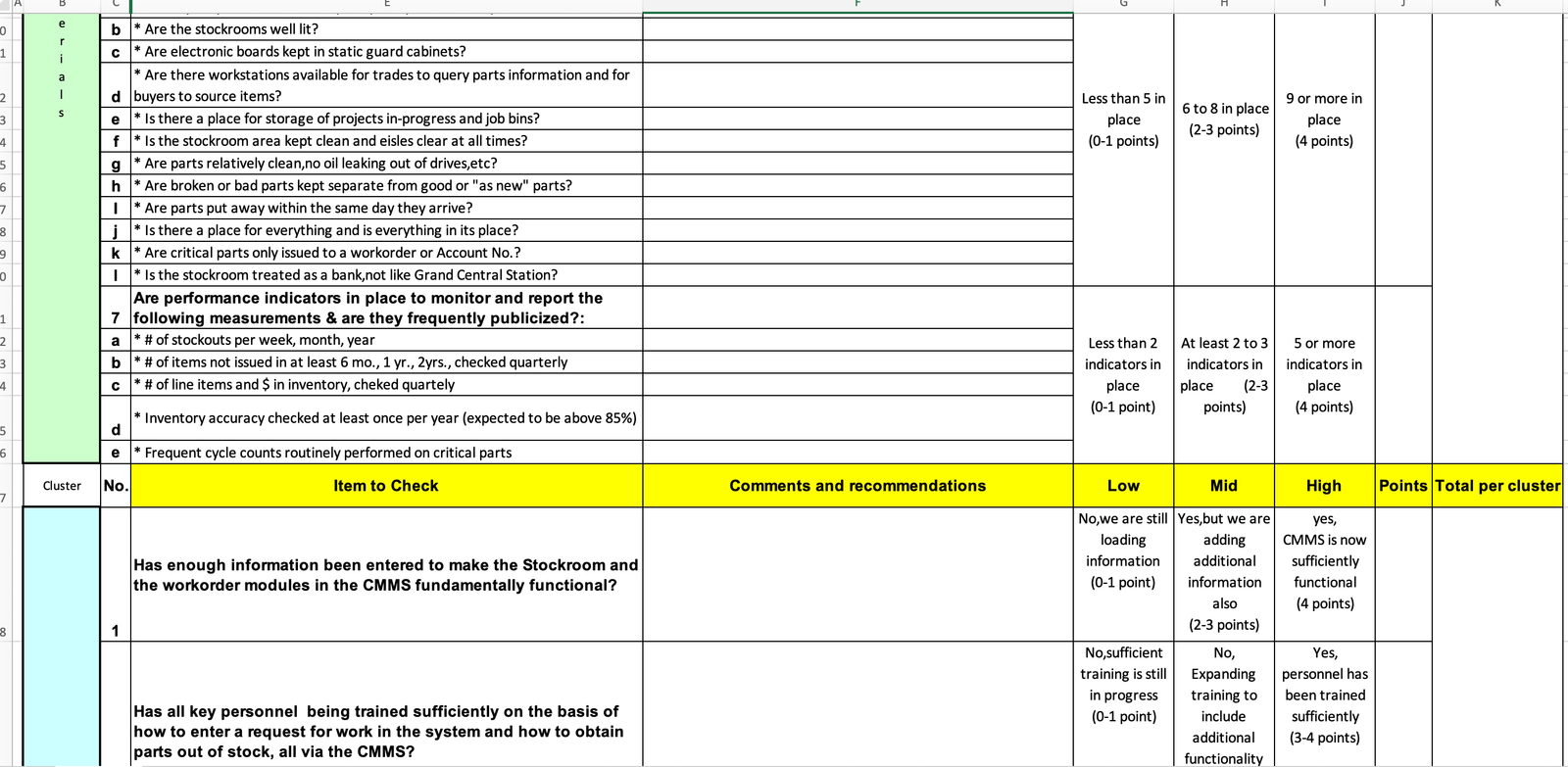

Introducing the Gap Analysis PM – Preventive Maintenance Optimization Spreadsheet, a comprehensive and user-friendly tool designed to streamline your preventive maintenance strategy, boost equipment efficiency, and minimize downtime. By performing a detailed gap analysis, you can identify areas for improvement and take actionable steps to optimize your maintenance processes.

Key Features:

- Equipment Inventory Management: Efficiently organize and categorize your assets, including equipment specifications, age, and maintenance history, in one centralized location.

- Customizable Maintenance Schedule: Easily create and update preventive maintenance schedules based on equipment type, age, and usage, ensuring consistent and timely maintenance.

- Maintenance Procedure Tracking: Review and update maintenance procedures to align with industry best practices and manufacturers’ recommendations.

- Resource Allocation Assessment: Evaluate and optimize the allocation of personnel, tools, and spare parts to support an effective preventive maintenance program.

- Maintenance Metrics Dashboard: Establish a system for tracking and analyzing key performance indicators such as mean time between failures (MTBF), mean time to repair (MTTR), and overall equipment effectiveness (OEE).

Benefits:

- Enhance equipment efficiency and extend equipment life.

- Minimize downtime and reduce maintenance costs.

- Streamline preventive maintenance processes and schedules.

- Facilitate continuous improvement through performance tracking and analysis.

- Simplify compliance with industry standards and manufacturers’ recommendations.

Reviews

There are no reviews yet.