Description

Summary of key points:

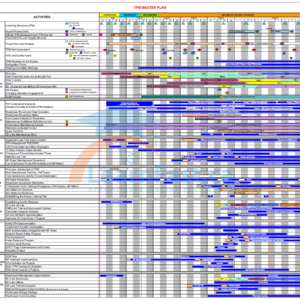

📅 Link the machine ledger with the PM calendar since the beginning.

📈 The machine ledger and PM calendar together is the single most powerful tool to drive maintenance results (cost and performance).

🛠️ They provide the horizontal view of your maintenance activities and improvement opportunities

📊 Track KPIs on a monthly basis to check the results

Acronyms used in the file:

C – Cleaning

I – Inspection

L – Lubrication

T – Tightening

QA – Quality Assurance

QA Matrix, you can read here: https://leanmanufacturing.online/qa-matrix/

QM – Quality Maintenance (TPM pillar aka “Quality”) https://learnfast.ca/courses/quality-maintenance/

AM – Autonomous Maintenance (TPM pillar) https://learnfast.ca/courses/autonomous-maintenance/

PM – Planned Maintenance (TPM pillar aka “Effective Maintenance”) https://learnfast.ca/courses/effective-planned-maintenance/

PM – Preventive or Preventative Maintenance, is a program that is regularly performed on a piece of equipment to reduce or eliminate the likelihood of it failing

SMP – Standard Maintenance Procedure

FI – Focused Improvement (TPM pillar) https://learnfast.ca/courses/focused-improvement/

TBM – Time-Based Maintenance

CBM – Condition-Based Maintenance

BDM – Breakdown Maintenance

You can find a detailed explanation of how to use this spreadsheet here:

https://leanmanufacturing.online/world-class-manufacturing-pm-machine-ledger-and-pm-calendar/

Rajinder Kumar –

Very useful tool to coordinate all PM activities by thinking at the component level.

Kelly Roberts –

We have successfully implemented PM calendar, which works as recurrence matrix and gives us visibility where to focus in order to achieve zero breakdown goal.