Autonomous Maintenance

- Business, Operations, TPM

- 311 (Registered)

-

(1 Review)

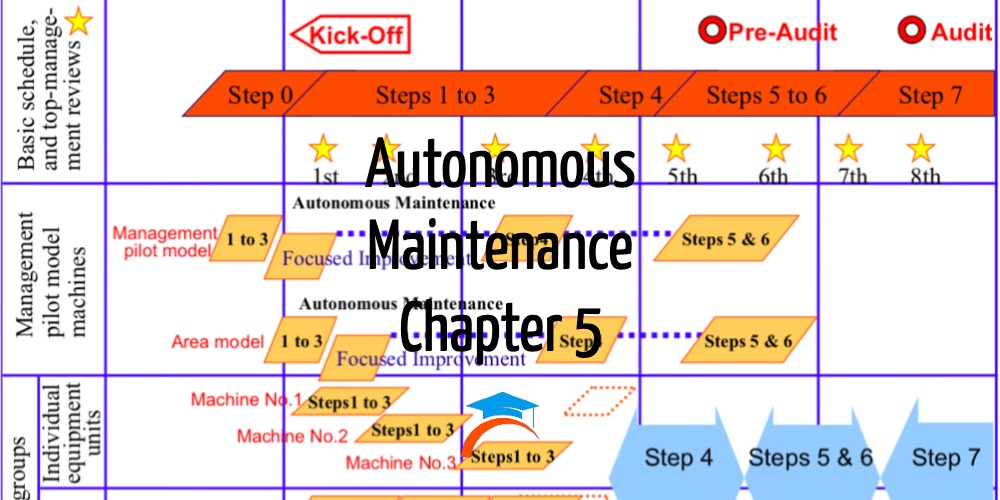

Chapter 5 of TPM Instructor Course.

Autonomous Maintenance (AM) aims to create a scenario where all operators look after their equipment, carrying out routine checks, oiling and greasing, replacing parts, doing simple repairs, spotting problems early, checking precision, and so on.

This chapter will describe the TPM methodology and activities of AM pillar as well as the seven steps to AM and how they work:

- “Correction is perfection” (reversing deterioration and making improvements brings good results)

- “Perfection is satisfaction” (getting good results gives a feeling of accomplishment)

- “Satisfaction is further action” (a feeling of accomplishment makes people want to achieve even more).

Upon completing the course with a 75% score or higher on the final quiz, the “Autonomous Maintenance Facilitator” certificate will be generated and can be purchased, link here. It can be downloaded and shared on your social media profile. Please refer to this forum’s post to get help adding a certificate to your LinkedIn profile.

Next chapter – Planned (Effective) Maintenance