Safety, Health and Environment

Free

- Business, Operations, Safety, TPM

- 146 (Registered)

-

(0 Review)

02

Apr

Chapter 11 of TPM Instructor Course.

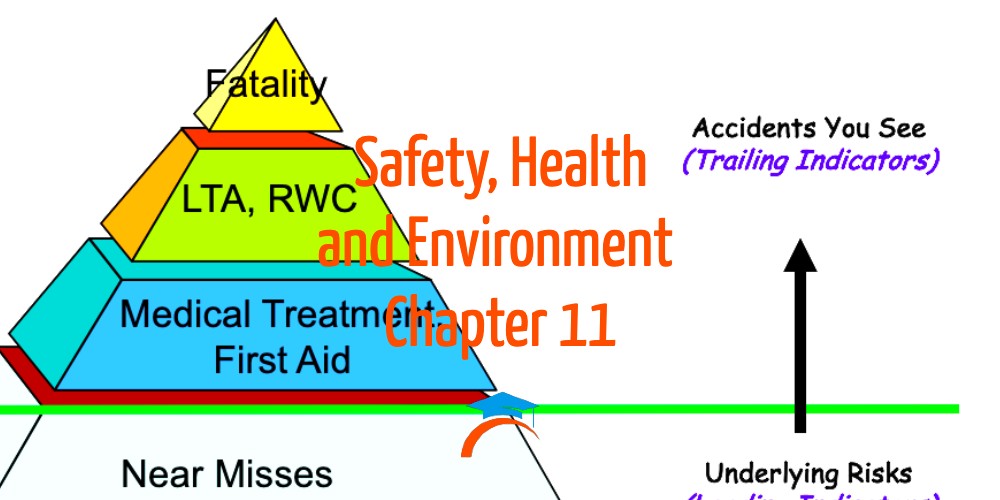

The basic approach to safety, health, and environmental management in TPM is multi-pronged. A zero-accident scenario must be achieved by eliminating every conceivable hazard or concern that might give rise to a safety incident.

SHE activities described in this chapter and elsewhere in this manual are only examples, and the decision as to whether or not to adopt a particular activity is left entirely up to the facility or company where the activity is to be performed.

Next Chapter – TPM Instructor Course