Quality Maintenance

Free

- Business, Operations, TPM

- 86 (Registered)

-

(0 Review)

30

Mar

Chapter 8 of TPM Instructor Course.

The only way we can achieve our goal of zero quality defects is to discard the reactive, “shutting the stable door after the horse has bolted” type of approach, where we only examine quality after it has already been built into the product.

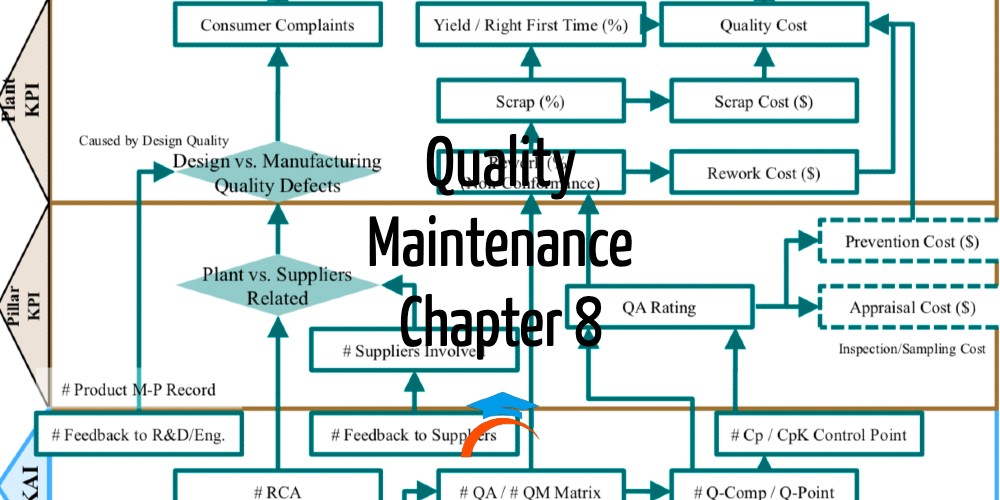

In this chapter will teach how build a system for controlling the causes of quality – in other words, establish and maintain the “zero-defect conditions” mentioned earlier. “Controlling quality through its causes” is the essence of Quality Maintenance.

Next Chapter – Education and Training

Curriculum

- 9 Sections

- 44 Lessons

- 10 Weeks

Expand all sectionsCollapse all sections

- The Need for Quality Maintenance1

- What is Quality Maintenance?1

- The Basic Philosophy of Quality Maintenance3

- Prerequisites for Promoting Quality Maintenance2

- Developing Quality Maintenance (A 10-Step Procedure)12

- 6.1Carrying Out Quality Maintenance

- 6.2Step 1 Verify the Existing Situation

- 6.3Step 2 Investigate the Processes where Defects Occur

- 6.4Step 3 Investigate and Analyze 4-M Conditions

- 6.5Step 4 Plan Action to Correct Deficiencies

- 6.6Step 5 Analyze Situations where the Conditions for Building in Quality Are Unclear

- 6.7Step 6 Eliminate Flaws in 4-M Conditions

- 6.8Step 7 Finalize 4-M Conditions

- 6.9Step 8 Consolidate Checking Methods

- 6.10Step 9 Determine Standard Values for Checks

- 6.11Step 10 Revise Standards

- 6.12Results

- The Figure-of-Eight Method for Quality Maintenance2

- Quality Maintenance in a Manual Operation7

- 8.1Step 1 Identify Existing Situation (Clarify Quality Characteristics and Work Conditions)

- 8.2Step 2 Restore (Assess Control Level and QA Level, and Calculate Process QA Rate)

- 8.3Step 3 Analyze Causes (Investigate Relationship between QA Level and Defects (In-Process Defects and Passed-On Defects)

- 8.4Step 4 Eradicate Causes (Establish Improvement Targets)

- 8.5Step 5 Establish Conditions (Propose Improvements and Implement)

- 8.6Step 6 Improve Conditions (Check Results and Evaluate)

- 8.7Step 7 Maintain Conditions (Consolidate Gains and Sustain)

- Quality Maintenance in Manual Work Processes8

- P-M Analysis in Eight Easy Steps8

- 10.1Step 1 Clarify Phenomenon

- 10.2Step 2 Do Physical Analysis of Phenomenon

- 10.3Step 3 Identify Contributing Conditions

- 10.4Step 4 Study 4-M Correlations

- 10.5Step 5 Revise Optimal Conditions (Standards)

- 10.6Step 6 Investigate Measurement Methods

- 10.7Step 7 Identify Deficiencies

- 10.8Step 8 Restore, Improve and Sustain