Safety, Health and Environment

Free

- Business, Operations, Safety, TPM

- 158 (Registered)

-

(1 Review)

02

Apr

Chapter 11 of TPM Instructor Course.

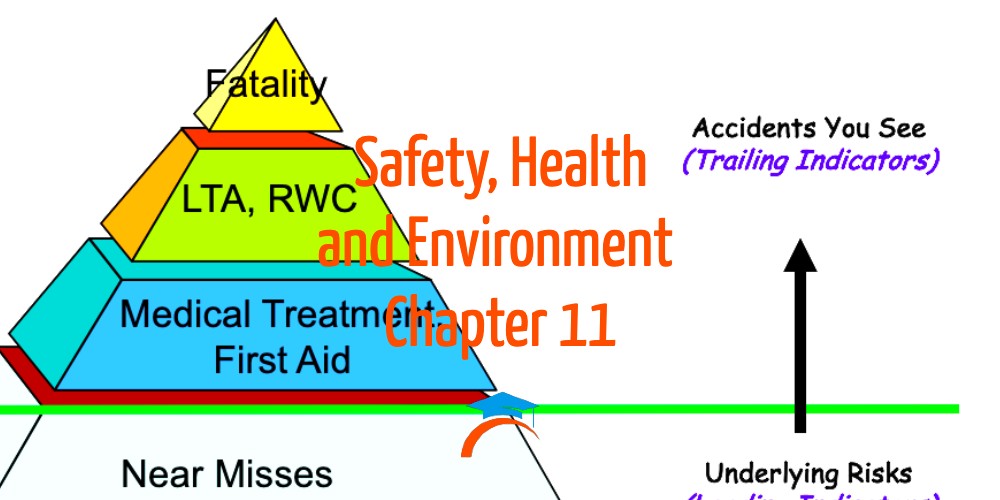

The basic approach to safety, health, and environmental management in TPM is multi-pronged. A zero-accident scenario must be achieved by eliminating every conceivable hazard or concern that might give rise to a safety incident.

SHE activities described in this chapter and elsewhere in this manual are only examples, and the decision as to whether or not to adopt a particular activity is left entirely up to the facility or company where the activity is to be performed.

Next Chapter – TPM Instructor Course

Curriculum

- 5 Sections

- 25 Lessons

- 10 Weeks

Expand all sectionsCollapse all sections

- The Importance of Safety, Health and the Environment2

- Safety Programs9

- 3.1Health and Safety and their Relationship with Productivity and Economy

- 3.2Workplace Incidents and Problems to Be Solved in Creating a Safe Workplace

- 3.3Why do People Fail to Observe Rules Properly?

- 3.4The Basic Approaches to Safety

- 3.5The Need for Full Involvement of All Employees

- 3.6Building a Companywide Safety Management Structure

- 3.7Safety Activities Combining Management and ahe Shop Floor

- 3.8Using Safety Tags and Maps

- 3.9Examining Past Accidents and Analysing Data

- Creating Worker-Friendly Workplaces3

- Towards a Recycling-Oriented Society5

- Management Indicators6

- 6.1Result Based SHE indicators

- 6.2Establishing a Safety Management Organization and Safety Committees

- 6.3Items to Be Checked at the Preparation Stage

- 6.4Investigating and analyzing, reviewing hazards, and making improvements

- 6.5Strategies for dealing with points that are difficult to resolve

- 6.6Reducing fatigue